Week three was primarily dedicated to working on our projects so I’ll start with…

Project update:

On Monday I checked the shipping of the bamboo veneer that I purchased and it was scheduled to arrive on Thursday. To me, building a longboard in 7 days sounded daunting, so I decided to make a prototype. After calling all the lumber yards and Menards in the immediate area I learned that you really can’t find any wood cut to less than 1/4″ thickness. With this in mind I wanted to find something more reasonable that would let me refine some skills but would actually work as a board, at least once. I went to the North Shed here on campus at Maharishi University and found some locally harvested cherry that still had a live edge. I decided to use that to prototype: first plaining the board to 2/3″, then tracing my board shape, then cutting out the shape, sanding it down, and finally adding the spar urethane clear coat. Because the spar urethane takes four hours to set I was only able to complete two coats on the front of the board, but this week I will finish it with three coats on each side.

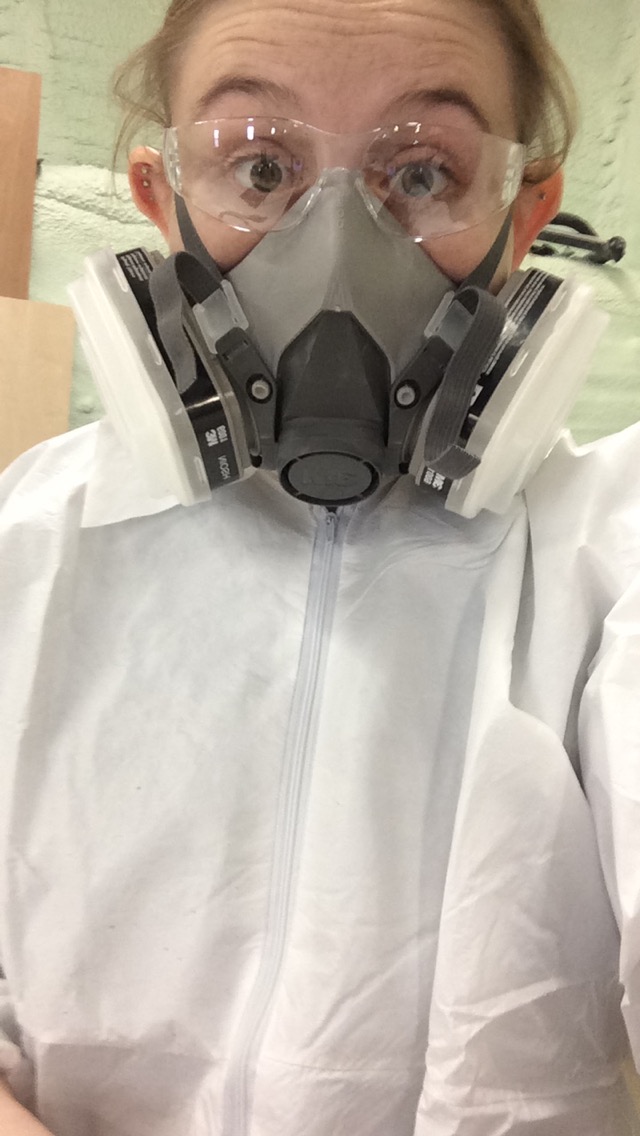

On Thursday afternoon the bamboo was delivered and I began setting up for pressing the five bamboo sheets into one on Friday morning. By the end of class Friday I glued the sheets together and used all the clamps I could find to maintain pressure on the sheets to make one solid board. I let it dry all night and on Saturday I unclamped and was happy to find that the process had worked well, with some minor imperfections. I worked Saturday afternoon and for about 11 hours on Sunday cutting, sanding, routing, sanding, designing the board art, painting, and doing the first clear coat of epoxy (I used epoxy instead of spar urethane because it adds structural strength). The first issues this week was the delay in bamboo, and my need for speed while working my prototype. I was getting impatient on the bandsaw and started going quick resulting is some gouges that took me extra time to sand. The major issue though was when I was clamping my bamboo veneer. As the pressure from the clamps wasn’t even along the whole board, there were areas that didn’t press as tightly, and even some cracking along the seams of bamboo. This was very disheartening as I waited for the wood glue to dry, but when I removed the clamps and got everything shaped and sanded I found that everything I was worried about was either mended or not actually a problem. The next major setback was what I like to call “The Routing Apocalypse of 2016” in which I successfully mutilated my board into a mess of a shape and had to spend three hours hand-sanding to fix it… but what’s a little blood, sweat, and tears if it’s for something you can be proud of? At this point I have everything I need to complete both boards 😀

^My makeshift press!

^My makeshift press!

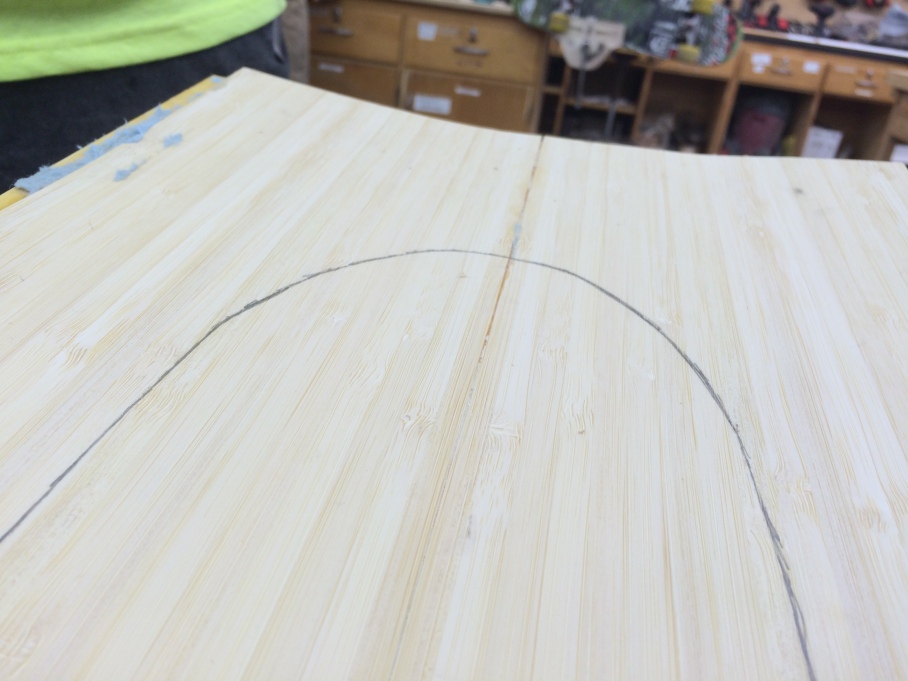

^Drawing the shape!

^Drawing the shape!

^I knew I heard something crack!

^I knew I heard something crack!

^Slow and steady with the bandsaw!

^Slow and steady with the bandsaw!

^Taking a break from cutting to add another spar urethane coating the prototype!

^Taking a break from cutting to add another spar urethane coating the prototype!

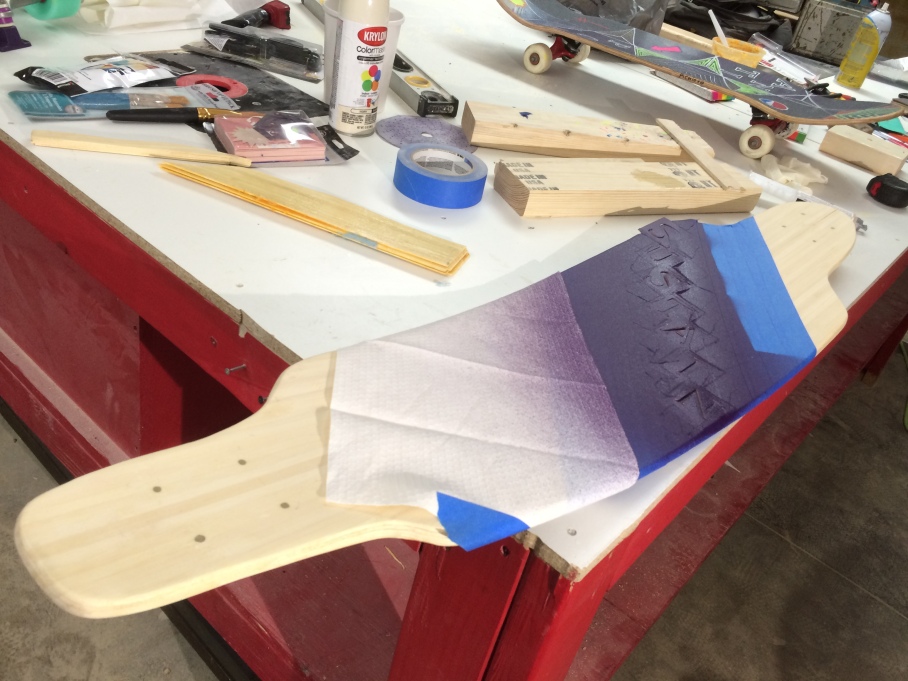

^Spraypainting the design!

^Spraypainting the design!

^Adding the epoxy coat!

^Adding the epoxy coat!

^Leaving it in a safe place to dry!

^Leaving it in a safe place to dry!

Because my team mate, Danny, was sick on Friday and Saturday, I really just jumped right into the build alone (with my youtube tutorials and instructables.com to help). I really learned a lot though and I hope to pass that knowledge to Danny as he begins his build Monday.

Besides working hard all week on projects we had a few great speakers come in to give lectures. The lectures included inventions, open-source technologies, update on the recent permaculture convention, and an optional smithing lecture/demo. I really enjoyed the lecture on inventions because we really got a feel for what it takes to create something totally new and then assess the possibilities of making a profit out of it. This was necessary for me to understand the legal side of creating, while we go through this process, and I am inspired to use this knowledge to solve problems in the future as well as bring those techniques to others. I also really enjoyed the smithing demo because I feel that that is a skill that I would love to cultivate. I realized that it is not complicated but it is extremely challenging. I hope to be able to fire up the forge and play around with making a few things for my house.

I feel that this week really showed me why people make things. It is the dedication to detail, the power of the love and energy you put into it, and the fulfillment of critical thinking and problem solving. To make something is so much more than production value; making things is about all the values coming together to create a whole that is much greater than the sum of its parts. Though this is in the context of a specific thing, the lessons I am learning are a mere reflection of the totality of life. The struggles, the successes, the process, and ultimate triumph of completion is reflected in everything we do, not only in the things we make.